Execution of the works

Implementation of the demostration sections

The goal of implementing the demonstration sections is to conduct a long-term study of the acoustic and performance behaviour of the different noise-reducing mixes (LIFESOUNDLESS mixes) designed and previously validated within the scope of the project.

The main variables in the optimal design of LIFESOUNDLESS mixes were the percentage of recycled materials employed and sieve analysis in looking for gaps of around 12% in the mixture. From a total of 22 compositions studied, 5 different noise-reducing mixes were chosen for implementing them in both demonstration projects. This choice was based on analyzing the results obtained in the lab in the mechanical characterization of the mixes (maximum density, apparent density, gaps, conserved resistance, permanent deformation, etc.) and in their acoustic behaviour (acoustic absorption test with Kundt tube and mechanical impedance test).

Prior to implementing the demonstration projects, an initial diagnosis was made of the current acoustic situation in the sections where they were going to be built. The acoustic characterization was performed on three different levels:

- Review of the data collected in the strategic noise maps made in 2015;

- Detailed diagnosis based on installing local sampling stations over a 24-hour period with a 5-minute sampling interva;

- Monitoring campaign of the demonstration sections for the purpose of quantifying the effectiveness of the proposed solutions. Monitoring was conducted with the CPX (Close ProXimity Method), which provides data on the level of road noise, and the SPB (Statistical Pass-By Noise) Method, which measures traffic noise level. To complement acoustic characterization, the macro-texture and surface regularity of the road surface was assessed, since they have an influence on the initial road noise and consequently help us to interpret the results.

Finally, two settings were chosen, one on intercity road A-8058 “from Seville to Puebla del Río”, between kilometre points 3+350 and 3+870, and the other between KPs 2+100 and 3+100 on road A-376 “from Seville to Utrera”.

Setting 1: Test section on road A-8058

The action takes place within the municipal district of Gelves, between KPs 3+350 and 3+870 on road A-8058, which links Seville capital with Puebla del Río.

This is an intercity section on a dual carriageway connecting several conurbations situated along the road. It presents ADT (Average Daily Traffic) of around 30,000 vehicles per day, low speed (of less than 50 km/h) and a low percentage of heavy traffic.

|  |

1. Location of the action

|  |  |  |

2. Previous state

For this test section on road A-8058 two SMA8 mixes were selected, with different percentages of bitumen and rubber additive from Scrap Tires for Road Construction.

|

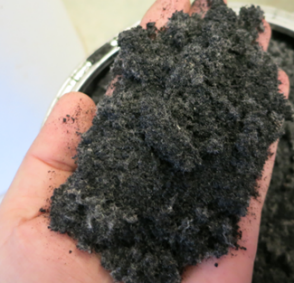

3. Rubber from Scrap Tires

- Right-hand roadway (Gelves direction): spreading of SMA8 mix with 6% bitumen and 1% rubber in the mix.

- Left-hand roadway (Seville direction): spreading of SMA8 mix with 6.5% bitumen and 1.5% rubber in the mix.

|  |

4. Works prior to spreading (milling and replacement)

|  |

5. Mix spreading works

|  |

6. Putting into service

Setting 2: Test section on road A-376

The action takes place on the urban section corresponding to the town of Montequinto, between KPs 2+100 and 3+100 of road A-376 linking Seville capital with Utrera.

This is a ring road urban section of a double carriageway with high ADT (around 80,000 vehicles/day), with an average speed (between 70-80 km/h) and a higher percentage of heavy traffic than the urban section (of close to 5%).

|  |

7. Location of the action

|  |  |  |

8. Previous state

Three types of SMA8 mixes were spread in this section, with the addition of different recycled materials. Specifically, these were the choices:

- Right-hand roadway (Utrera direction): spreading of an SMA8 mix with 1.0% of recycled plastic.

- Left-hand roadway (Seville direction): spreading of an SMA8 mix with 0.5% of recycled plastic and 0.5% of powdered rubber.

- Service road on right-hand side (Utrera direction): spreading of an SMA8 mix with 0.5% recycled nylon fibres.

|  |  |

9. Recycled materials (recycled plastic, rubber and nylon from Scrap Tires)

In addition, on the right-hand roadway a 200-metre-long reference section was spread with a conventional ophitic AC16 surf 35/50 S mix. This type of reference mixture has been employed because it is the habitual road surface mix used by the Development and Housing Department of the Junta de Andalucía Government in road refurbishment. This will thus establish a comparison between the behaviour of conventional mixes and that of the new LIFESOUNDLESS mixes.

|  |

|  |

|

10. Mix spreading works

|  |

11. Putting into service

After putting the different LIFESOUNDLESS mixes into service in both demonstration projects, 5 acoustic surveying campaigns will be conducted (measuring sound indicators according to the CPX, Close Proximity Method, and SPB, Statistical Pass-By Noise Method) and of surface auscultation (macro-texture measuring according to the MTD volumetric method and the profilometric (MPD) and surface regularity method using the Surface Regularity Index (SRI) every 6 months.

La consejería

La consejería